YGT

Product Description

Heat exchangers are key components in the food, beverage and pharmaceutical industries, used to heat, cool and pasteurize liquids by transferring heat between two fluids (without mixing). It ensures energy efficiency, precise temperature control and product safety.

|

|

>>>Feature and Advantage:

High heat transfer efficiency – Plate and tube design maximizes heat exchange.

Energy-efficient operation – Efficient heat recovery reduces energy consumption.

Compact and space-saving – Optimized design for easy integration into production lines.

Precise temperature control – Automation ensures continuous heating/cooling.

Hygienic and CIP-compatible – Designed for easy cleaning and maintenance.

Versatile – Suitable for milk, juice, seaweed juice, beer and other liquids.

Production process:

Step 1: Fluid Entry

The product and heating/cooling medium enter separate channels within the heat exchanger.

Step 2: Heat Transfer

The heat is transferred between the two fluids via a conductive surface (plates or tubes), heating or cooling the product.

Step 3: Temperature Control

The PLC-based automation system regulates the temperature to maintain optimal processing conditions.

Step 4: Discharge and Further Processing

The processed fluid exits at the desired temperature, ready for pasteurization, sterilization, or further processing.

>>>Working principle:

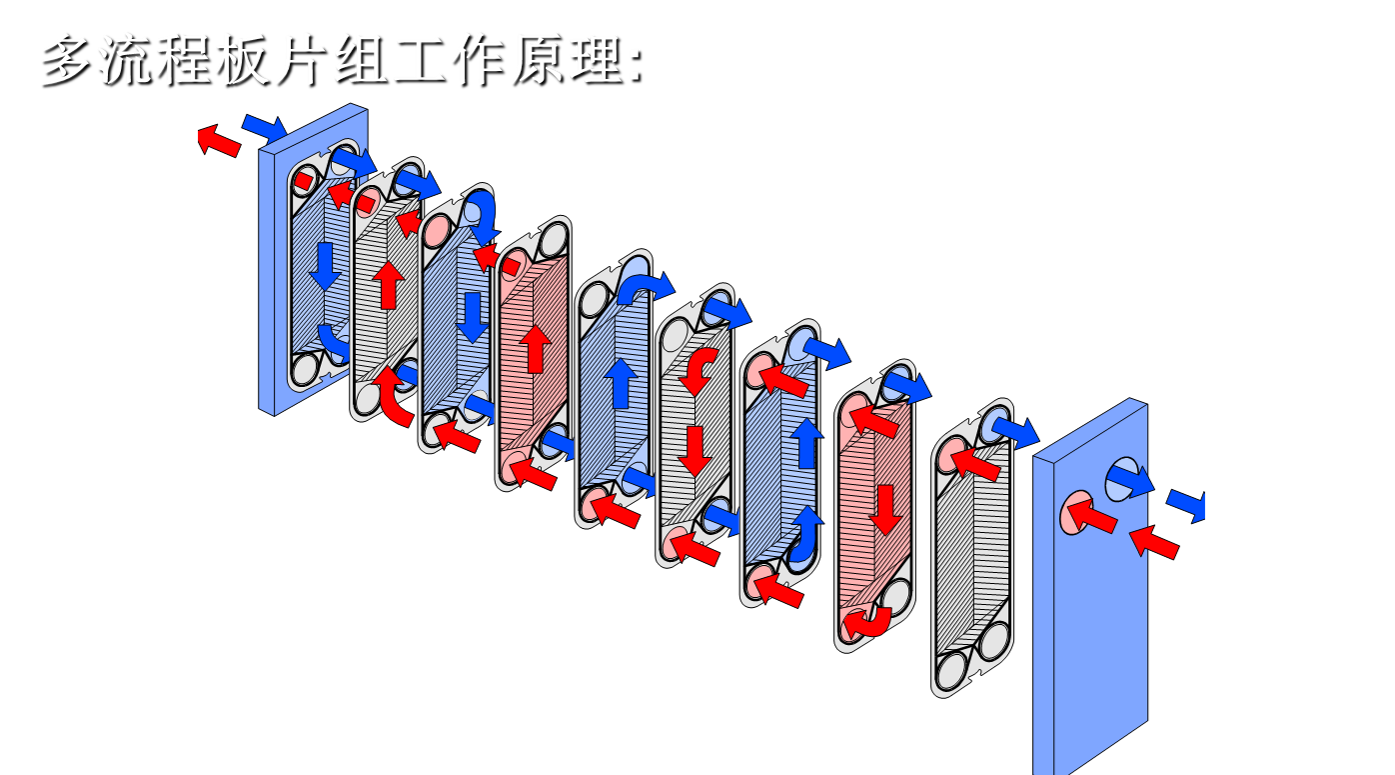

Heat exchangers work by passing hot and cold fluids through different channels, transferring heat between them via conduction surfaces. The main types include:

Plate Heat Exchangers (PHE) – use stacked plates to maximize heat transfer efficiency.

Tube Heat Exchangers – use tubes to handle high viscosity liquids such as sauces and pastes.

Shell and Tube Heat Exchangers – common in large industrial applications.

Technical parameter:

| Specification | Details |

| Processing Capacity | 500 – 5000 L/h (customizable) |

| Heat Transfer Efficiency | 90% - 98% |

| Temperature Range | -10°C to 150°C |

| Heat Exchange Area | 5 – 200 m² (varies by model) |

| Material | SUS304 / SUS316L Stainless Steel |

| Heat Source | Steam / Hot Water / Electric Heating / Chiller |

| Control System | PLC + Touchscreen Automation |

| Cleaning System | CIP (Clean-in-Place) Compatible |

| Application | Dairy, Juice, Seaweed Juice, Beverages, Pharma |

Application:

Food and Beverage - for juice pasteurization, dairy processing and brewing.

Dairy Industry - heating and cooling of milk in production lines.

CIP Cleaning Systems - heating water for equipment disinfection.

|

|

|

Service:

1. Installation and Training: Our team provides online, on-site installation and operator training to ensure smooth operation.

2. Warranty and Spare Parts Warranty: Major components are covered for 1 year.

3. Technical Support: We provide online support, video assistance and on-site troubleshooting if needed.

4. Preventive Maintenance Program: Regular service programs help keep your machine running efficiently and extend its life.

>>>FAQ:

Q1: What are the uses of heat exchangers in food and beverage production?

A: It is used to efficiently heat, cool or pasteurize liquids while maintaining product quality.

Q2: What are the different types of heat exchangers?

A: Plate Heat Exchanger (PHE) – Best for fast heat transfer and easy maintenance.

Tubular Heat Exchanger – Suitable for thick, viscous liquids.

Shell and Tube Heat Exchanger – Used in large industrial applications.

Q3: How do heat exchangers improve energy efficiency?

A: By recovering and reusing heat, energy waste and operating costs can be reduced.