YGT

Product Description

High performance industrial homogenizers are designed to break down and evenly distribute particles in liquid products, thereby improving stability, texture and shelf life. They are widely used in the food and beverage, dairy, pharmaceutical, cosmetic and chemical industries.The machine is made up of the foundation, motor, gearbox, high pressure pump and homogenizing component etc.

|

|

|

>>> Feature and Advantage:

Ultrafine particle size reduction

Enhanced product stability and uniformity

Energy-saving operation

Made of 316L stainless steel, hygienic and durable

Fully automatic PLC control system

Configuration:

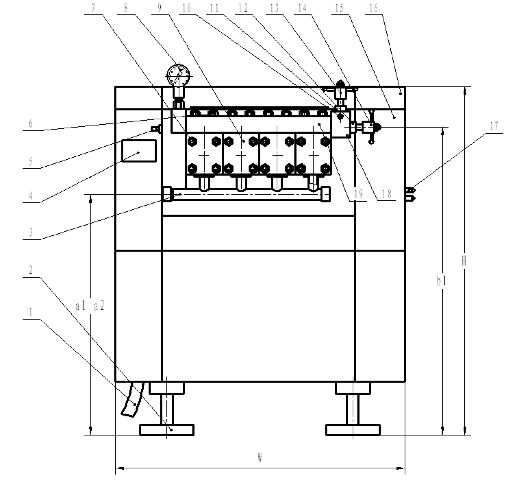

1.cool water output port 2. base foot 3. suction manifold 4. nameplate 5. cool water input port 6. pressing cover 7. nut for pump body 8.pressure gauge component 9. pump body 10. product output port 11. low pressure hand-wheel seat 12. high pressure hand-wheel seat 13. low pressure hand-wheel 14. high pressure hand-wheel 15. shell 16. top cover 17. power switch(depending on machine type) 18. valve body

>>>Working Principle:

when product is flowing through the adjustable valve ,the particles or droplets present in mixed fluids with high pressure will be subdivided into the very smallest sizes (diameter Φ=0.1~0.2 um, average Φ ≤1um ) because of pressure decrease, expansion, explosion, cutting and high-speed impacting etc., then the emulsions or dispersions could be produced. This process refer to the following Fig.

Through homogenizing the stability, easy-absorb, long-life, taste and color etc. of product could be realized.

Technical parameter:

Driving assembly | House is made of grey cast iron HT200, and crank shaft, connecting rod, and gears are made of ductile cast iron. |

Plunger | the 4th generation stainless alloy(PH-type). |

Check valve | the 4th generation stainless alloy (GrMoFr), abrade-resisting and impact-resisting. |

Pump block | stainless steel |

Plunger sealing | X4310 and PP spacer with heat-proof reaching 100℃. |

Homogenizing valve | the 3rd special stainless alloy |

All the above-mentioned material is according with sanitary rules and suitable for CIP cleaning. | |

Application:

(1) cell disruption, process new products, or harvesting the intracellular products;

(2) subdividing the particles or droplets present in fluids into very smallest sizes ( submicron )

and creating a stable dispersions and emulsions;

(3) homogenizing many other products;

Widely applied in fields of food, genetic engineering, chemical industry, pharmacy etc.

|

|

|

Service:

1. Installation and Training: Our team provides online, on-site installation and operator training to ensure smooth operation.

2. Warranty and Spare Parts Warranty: Major components are covered for 1 year.

3. Technical Support: We provide online support, video assistance and on-site troubleshooting if needed.

4. Preventive Maintenance Program: Regular service programs help keep your homogenizer running efficiently and extend its life.

>>> FAQ:

Q:What is a homogenizer used for?

A:Homogenizers are used to break up and evenly distribute particles in liquids, improving stability, texture, and shelf life. It is widely used in the dairy, juice, cosmetics, pharmaceutical, and chemical industries.

Q:Can homogenizers handle different viscosities?

A:Yes, our homogenizers are designed to handle a wide range of liquid viscosities, from thin juices to thick creams and pastes.

Q:Do you offer customization services?

A:Yes! We can customize the capacity, pressure levels, and control systems to meet your production needs.